High Speed CNC Angle Punching Marking and Shearing Machine

Product Details:

- Product Type Best Price CNC Angle Steel Punching Marking Shearing Machine Use High Voltage Tower

- Automatic Yes

- Power Source Electric

- Warranty Yes

- Click to View more

High Speed CNC Angle Punching Marking and Shearing Machine Price And Quantity

- 61000.00 - 65000.00 INR/Unit

- 1 Unit

High Speed CNC Angle Punching Marking and Shearing Machine Product Specifications

- Yes

- Yes

- Best Price CNC Angle Steel Punching Marking Shearing Machine Use High Voltage Tower

- Electric

High Speed CNC Angle Punching Marking and Shearing Machine Trade Information

- 10 Unit Per Day

- 30 Days

Product Description

I. Application Field

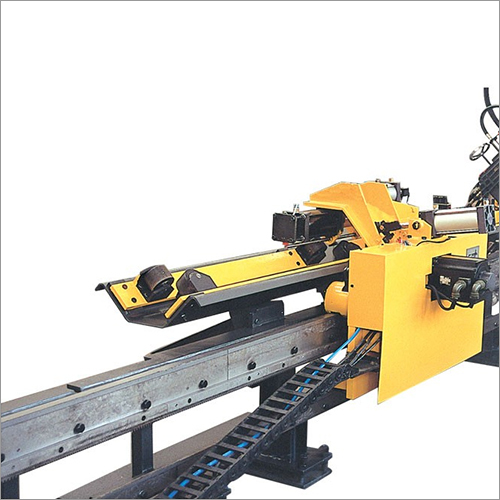

This equipment serves as a professional production apparatus in the angle steel tower industry, primarily applied to the processing procedures of angle steel punching, marking, and shearing. It provides an efficient and precise integrated solution for angle steel tower manufacturing.

II. Product Composition

The equipment consists of two major parts: the mechanical transmission system and the intelligent control system.

The mechanical transmission system includes the transverse conveying device, rotating loading mechanism, feeding transmission component, CNC feeding carriage, punching operation unit, marking processing unit, cutting execution unit, and unloading conveying device.

The intelligent control system integrates the hydraulic drive system, electrical control system, and pneumatic execution system. Through precise design and modular integration, each component ensures the stable operation of the equipment and high processing efficiency.

III. Product Features

1. Advanced CNC Technology with Excellent Performance Assurance

Equipped with a Computer Numerical Control (CNC) system and servo motor feeding drive technology, it enables highly efficient automated production, ensuring stable and reliable precision in workpiece processing. The key hydraulic, pneumatic, and electrical components of the equipment are all imported from internationally renowned brands, guaranteeing the stability and durability of the equipment from a hardware perspective.

2. Flexible Die Configuration for Efficient Model Changeover

Both sides of the equipment are equipped with three sets of combined punch and die components, supporting the installation of punches with three different diameter specifications. This setup flexibly meets diverse hole diameter processing requirements. The coordinated control of the three sets of dies by the Programmable Logic Controller (PLC) enables quick switching of punching back mark parameters, significantly reducing production changeover time and enhancing production flexibility.

3. Intelligent Interactive Interface for Convenient Programming and Operation

The equipment is equipped with an industrial control computer featuring a bilingual (Chinese and English) operation interface. It has an intuitive and visual workpiece drawing display function, which greatly lowers the operation threshold. It supports direct import of program data generated by mainstream lofting software. During the programming process, only workpiece size parameters, hole diameter specifications, back mark information, and processing quantity need to be inputted, and the system can automatically generate the optimal processing path, effectively improving programming efficiency and accuracy.

4. Closed-Loop Precision Control for Guaranteed Positioning Accuracy

The CNC feeding carriage is driven by a servo motor and, in conjunction with a high-precision photoelectric encoder that provides real-time position feedback, constructs a full closed-loop control system. This enables precise positioning and error compensation during equipment operation, ensuring that the positioning accuracy during processing reaches the leading level in the industry.

5. Full-Process Automation for an Optimized Production Experience

The equipment integrates automated marking, punching, and shearing functions, achieving full-process automated operation of the processing procedures. Finished workpieces are automatically unloaded by the pneumatic turnover unloading device, effectively reducing the labor intensity of operators while enhancing production safety and operational efficiency.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+