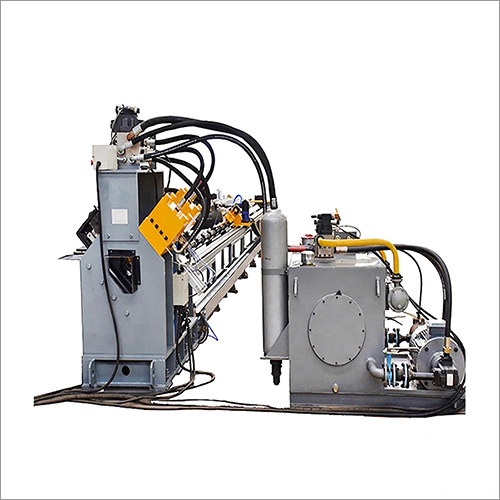

Cheap Price CNC Angle Drilling And Marking Machine for Angle Steel Tower Industry

Product Details:

- Product Type CNC Angle Drilling And Marking Machine Model JNC2532/JNC2532G

- Power Source Electric

- Warranty Yes

- Click to View more

Cheap Price CNC Angle Drilling And Marking Machine for Angle Steel Tower Industry Price And Quantity

- 1900000.00 - 2000000.00 INR/Unit

- 1950000 INR/Unit

- 1 Unit

Cheap Price CNC Angle Drilling And Marking Machine for Angle Steel Tower Industry Product Specifications

- CNC Angle Drilling And Marking Machine Model JNC2532/JNC2532G

- Electric

- Yes

Cheap Price CNC Angle Drilling And Marking Machine for Angle Steel Tower Industry Trade Information

- 10 Unit Per Day

- 30 Days

Product Description

Product Application

This equipment is a specialized solution for angle steel drilling, marking, and related processing in the angle steel tower industry. It is designed to meet high-precision manufacturing requirements for tower structural components, ensuring efficiency and consistency in industrial production.

Product Features

1. High-Efficiency CNC Automation

Utilizes CNC technology and servo motor-driven feeding for rapid, high-precision processing, ensuring workpiece accuracy within tight tolerances.

Key components (e.g., hydraulic valves, servo motors, PLC) are sourced from internationally renowned brands to guarantee reliability and durability.

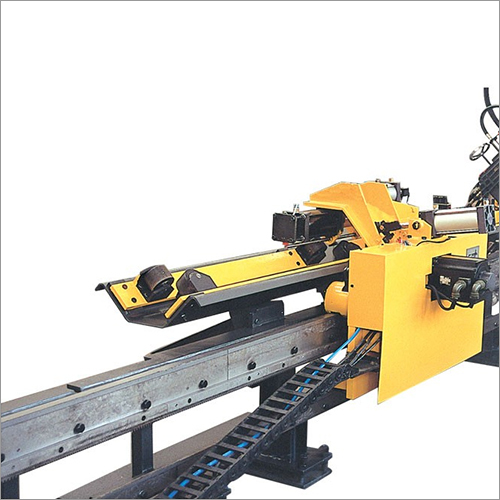

2. Flexible Multi-Drill Configuration

Dual-side drilling units each accommodate three drill bits of varying diameters, enabling seamless switching between different hole sizes.

CNC-controlled holistic movement of drilling units allows precise adjustment of drilling pitches (stadia), ensuring positional accuracy without manual retooling.

3. Precision-Driven Machining Parameters

Spindle rotation speeds are infinitely adjustable via frequency converters, while feeding speeds are controlled by proportional valves for optimal versatility.

Automated transitions between rapid feeding, working feed, and rapid retraction enhance efficiency and reduce cycle times.

4. Integrated Marking & Hydraulic Clamping

The marking unit supports pre-programmable marking pitches, enabling quick adaptation to different workpiece specifications.

Hydraulic-driven workpiece clamping and feeding ensure stable positioning during processing.

A dedicated cooling system minimizes drill bit wear and maintains consistent machining quality.

5. Fully Automated Workflow

Marking and drilling operations are fully automated, eliminating manual intervention and reducing labor costs.

Pneumatic turnover devices enable automatic unloading of finished products, enhancing operator safety and reducing physical workload.

6. Intuitive Programming & Control

The control system, comprising a host computer, PLC, and servo motors, generates processing programs automatically based on inputted workpiece dimensions.

Programs can be saved, retrieved, displayed, and transmitted by workpiece number for efficient production management.

7. Enhanced Structural Adaptability

Built-in supporting and pressing devices accommodate angle steel with significant bending, ensuring stable processing for diverse workpiece geometries.

8. Advanced Diagnostic Capabilities

The system incorporates self-diagnostic functions to identify and report faults promptly, minimizing downtime and improving maintenance efficiency.

Technical Advantages

Precision: Closed-loop control and imported components ensure hole positioning accuracy and dimensional consistency.

Flexibility: Multi-drill configuration and quick-change tooling support high-mix production.

Reliability: Industrial-grade design and self-diagnostic features enhance uptime and reduce operational risks.

Operational Ease: User-friendly HMI (Human-Machine Interface) and automated workflows lower training requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+