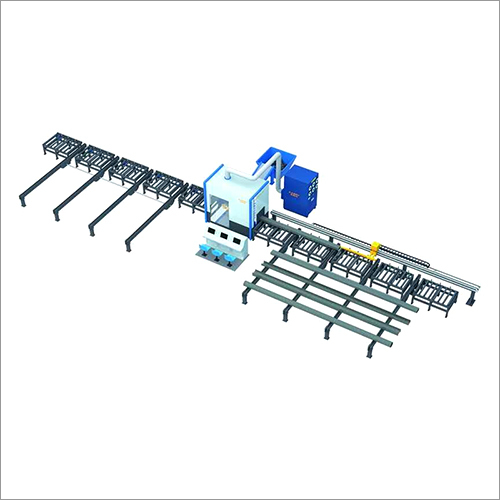

Automatic H beam Drilling machine steel punching machine steel drilling machine

Product Details:

- Type [ ]

- Feature [ ]

- Click to View more

Automatic H beam Drilling machine steel punching machine steel drilling machine Price And Quantity

- 1 Forty-Foot Container

- 80000.0 USD ($)

Automatic H beam Drilling machine steel punching machine steel drilling machine Product Specifications

- [ ]

- [ ]

Automatic H beam Drilling machine steel punching machine steel drilling machine Trade Information

- Qingdao

- g h t L / C ) ' r a p h i c T r a n s f e ( T / T ) ' ] t ( S i [ ' L e t t e r o f C r e d i t a t S i g h , ' T e l e g r

- 10 Forty-Foot Container Per Month

- 30 Days

- Yes

- r l e p o u s a m p a c t u s f o r i n f o r m a t i o n r e g a r d i n g o [ ' C o n t l i c y ' ]

- Container

- a , ' r t i c a ' , ' M d d h A m e r i l e E a s t ' ] [ ' A s i ' N o

- [ ]

- Iso Certificate

Product Description

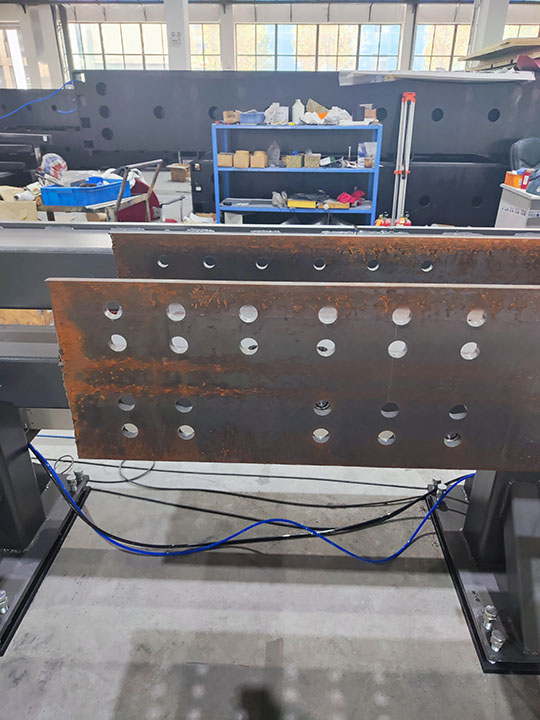

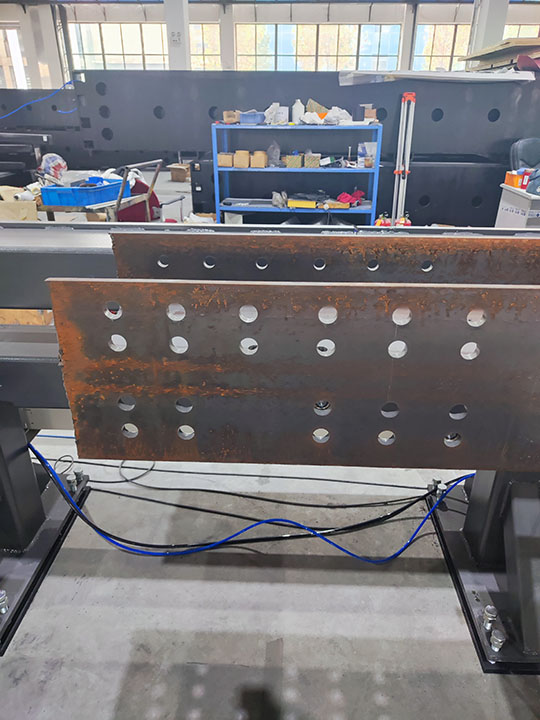

Automatic H beam Drilling machine steel punching machine steel drilling machineUse ofAutomatic H beam Drilling machine steel punching machine steel drilling machine

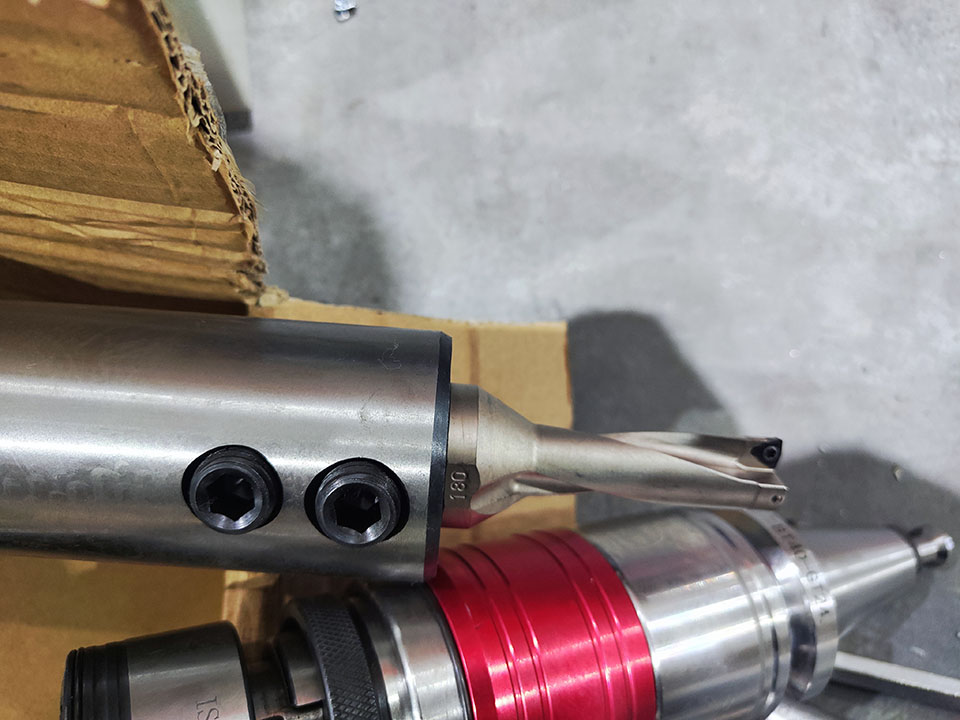

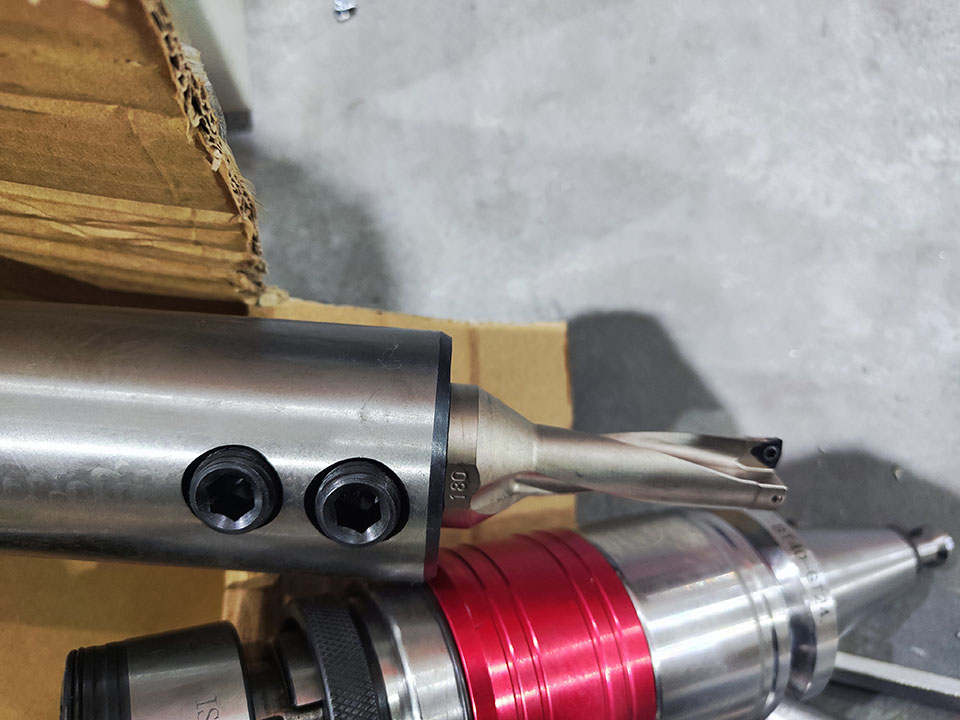

This production line is mainly used for sawing, drilling and punching and scribing of H-beam, channel and other steel profiles, and can also be equipped with typing unit. The drilling machine adopts three BT40 specification high-speed spindles to drill the three faces of steel sections, each face has one spindle, and the corresponding row-type tool magazine can accommodate up to four kinds of specification tools.

The drilling part of this production line can realize the conversion of CAD drawings into machining programs; and can realize multi-threaded synchronous operation, which can make reasonable arrangements for drilling, workpiece running, tool changing, spindle positioning, etc., so that two or three of them can be completed at the same time, which greatly improves the production efficiency.

Automatic H beam Drilling machine steel punching machine steel drilling machineconsists of two parts: a CNC three-dimensional drilling production line and a sawing channel. The electrical part is also divided into two parts, which control the feeding and discharging of the drilling and sawing machine power rollers respectively.

|

Parameter |

Value |

|||

|

Workpiece |

Width range of H beam |

100~700mm |

||

|

Height rangeof H beam |

100~500mm |

|||

|

Channel steel range (belly height x wing width) |

100x50~350x90mm |

|||

|

Angle size range |

100X100~250X250mm |

|||

|

length range |

2000~16000mm |

|||

|

Drilling spindle |

Quantity |

3 |

||

|

Model |

BT40 |

|||

|

Motor power |

15kW |

|||

|

Range of rotation |

100~3000r/min |

|||

|

Drilling diameter range |

5~40mm |

|||

|

CNC axis |

X-axis servo motor power |

About4.5kW |

||

|

Horizontal drilling positioning axis servo motor power |

About1.5kW |

|||

|

Vertical drilling positioning axis servo motor power |

About3kW |

|||

|

Drilling feed axis servo motor power |

About2kW |

|||

|

Precision |

Holedistance deviation |

Twoholeswithin 1 meter apart |

0.5mm |

|

|

The allowable deviation value increases by 0.2mm for every 1 meter increase in hole distance, and the maximum does not exceed 2mm. |

||||

|

End margin deviation |

1.0mm |

|||

|

Tapping |

M6~M12 |

|||

|

Marking unit |

Qty. of characters |

36 |

||

|

Character size |

10 |

|||

|

Hydraulic Disc typingunitScribingfunction |

||||