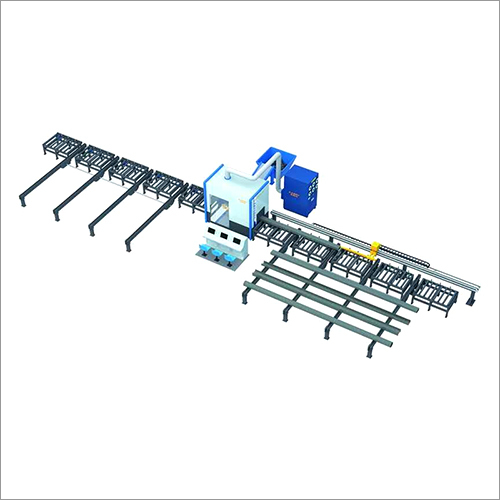

BHD1250C High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication

Product Details:

- Product Type High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication

- General Use Industrial

- Material Metal

- Weight (kg) 15000 Kilograms (kg)

- Automatic Yes

- Power Source Electric

- Dimension (L*W*H) 32000x6200x4000 Millimeter (mm)

- Click to View more

BHD1250C High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication Price And Quantity

- 180000.00 - 185000.00 USD ($)/Unit

- 1 Unit

BHD1250C High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication Product Specifications

- High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication

- Low Energy Consumption

- Metal

- 15000 Kilograms (kg)

- 32000x6200x4000 Millimeter (mm)

- Yes

- Yes

- Electric

- Industrial

BHD1250C High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication Trade Information

- 10 Unit Per Day

- 30 Days

Product Description

BHD1250C High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication is many machines capable and used to drill, ream or thread holes in a part. Drilling is the manufacturing process where a round hole is created within a workpiece or enlarged by rotating an end cutting tool, a drill. BHD1250C High Speed CNC H Beam Drilling Machine Line For Steel Structure Fabrication is the manufacturing process where a round hole is created within a workpiece or enlarged by rotating an end cutting tool, a drill.

Market: Worldwide

Specification

| H beam parameter | Max. Size Width x Height | 1250 x 600mm | |

| Min. Size Width x Height | 200x75mm | ||

| Max. Beam Length | 12000mm | ||

| Main spindle | Qty. | 3 | |

| Model | BT40 | ||

| Motor power | 3x11 kW | ||

| Spindle speed | 200 to 3000 r/min | ||

| Max. Hole diameter | 40 mm | ||

| Motor power | Feed servo motor power | 2x3 kW | |

| Positioning servo motor power | 2x3 kW | ||

| Processing Accuracy | Hole distance deviation | Two holes within 1 meter | -/+0.5 |

| The allowable deviation value increases by -/+ 0.2mm for every additional 1 meter of the hole distance, and the maximum does not exceed -/+ 2mm | |||

| End margin deviation | -/+ 1.0 mm | ||

| Hydraulic system | Hydraulic pump pressure | 7 MPa | |

| Oil pump motor power | 7kW | ||

| Electrical System | Control method | PLC | |

| Number of CNC axes | 7 | ||

| Overall size (L x W x H) | 32000x6200x4000 | ||

| Weight of main machine | About 15000kg | ||