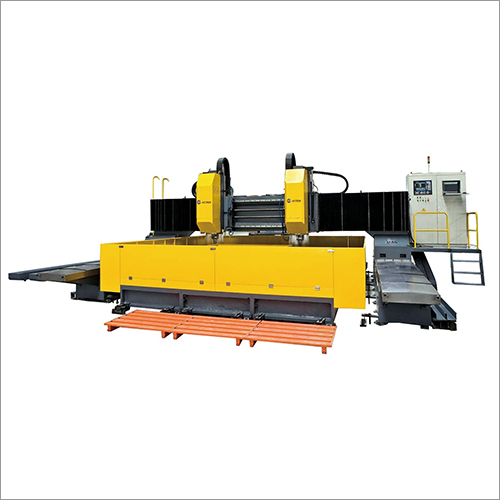

Stable and Durable CNC Plate Drilling Machine for High Precision Plate/Structural Component Machining

Product Details:

- Product Type Stable and Durable CNC Plate Drilling Machine for High Precision Plate/Structural Component Machining

- Power Source Electric

- Feature Low Energy Consumption, High Speed, High Precision

- Warranty Yes

- Click to View more

Stable and Durable CNC Plate Drilling Machine for High Precision Plate/Structural Component Machining Price And Quantity

- 1 Unit

- 85000.00 - 95000.00 USD ($)/Unit

- 50000 USD ($)/Unit

Stable and Durable CNC Plate Drilling Machine for High Precision Plate/Structural Component Machining Product Specifications

- Electric

- Yes

- Low Energy Consumption, High Speed, High Precision

- Stable and Durable CNC Plate Drilling Machine for High Precision Plate/Structural Component Machining

Stable and Durable CNC Plate Drilling Machine for High Precision Plate/Structural Component Machining Trade Information

- 10 Unit Per Day

- 30 Days

Product Description

1ãMachine bed and workbench:

The bed is welded and then annealed and then finely processed. It has excellent dynamic and static rigidity and does not deform. Two high-precision linear guides are installed on both sides of the bed base to make the guide sliders evenly stressed, greatly improving the rigidity and tensile and compressive resistance of the machine tool. The drive system uses AC servo motors and precision ball screw pairs for double-sided drive to move the gantry in the Y-axis direction. The workbench is also equipped with a hydraulic cylinder clamping system.

2ãMobile gantry:

The mobile gantry is made of gray iron (HT250) casting, and two ultra-high load-bearing rolling linear guides are installed on the front side of the gantry. A set of precision ball screws and a servo motor make the power head slide plate move in the X-axis direction, and the drilling power head is installed on the power head slide plate. The movement of the gantry is achieved by the servo motor driving the ball screw nut to rotate on the ball screw through the precision coupling.

3ãMobile saddle:

The mobile saddle is a precision cast iron structural part. Two ultra-high load-bearing CNC linear rail slides, a set of precision ball screw pairs and a high-precision planetary reducer are installed on the saddle to connect the servo motor. The weight of the power head is balanced to reduce the screw load and extend the service life of the screw. The drilling power head is driven to move in the Z-axis direction, which can realize the power head fast forward, working forward, fast backward, stop and other actions, and has the functions of automatic chip breaking, chip retreat and pause.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+